- 5 times stronger than all other rafter brackets - Minimum

- Made with high strength steel

- Only 2.5mm of deflection at the tile height when loaded to 1200kg

- LOWER COST than other Rafter Bracket Assemblies

- Special Design Large Oversized Washers Included to spread the load over a larger area

- 2 through holes allow for fitting of Eye Bolts in 4 directions

- Shade sail can be connected at any angle

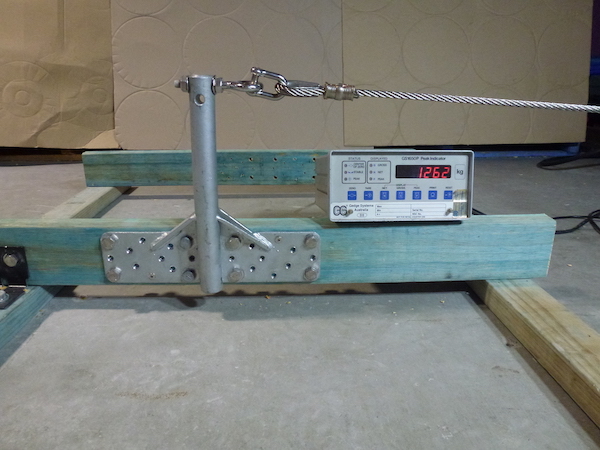

Picture 1 - Test shown above has Rafter Bracket fixed to 90 x 35mm structural pine MGP12. Load held static at 1250kgs for 7 days without failure.

FITTING NOTES

The RB-30 Rafter Bracket will handle a load of 1200kgs but your roof structure may not, and at this load your roof will probably need some strengthening. Refer to engineer when necessary.

If possible fit the Rafter Bracket to the junction of the roof truss and the wall top plate for the highest strength. Additional right angled brackets can be fitted at this junction to strengthen further when required.

If fitting to other parts of the truss, in higher load situations reinforce the truss using accepted methods. Refer to engineer when necessary.

High loads can be spread over multiple fixing points if required, add an eye nut to the M10 eye bolt thread. Tie the rafter bracket back to other rafter brackets or other anchor points.

Use all 8 of the M10 x 70mm bolts using the 8 bolt holes and 4 backing plates to achieve the best results. Use 10mm Drill bit to keep holes tight.

Avoid fixing near any knots in the rafter.

Use a double hex nut on the eye bolt to prevent the nut unwinding.

Shade sail connection can be made at any angle providing the eye of the eye bolt is tightened hard up against the rafter bracket. Orient the eye to suit the angle of connection.

The eye bolt can be used as a tensioner in place of a turnbuckle if the shade sail is pulling in direct line with the eye bolt direction. If this is desired, fit a brass nut to the eye bolt for tensioning, this can prevent seizing, go slowly and take note of heating parts. This method can eliminate the cost of a turnbuckle.

Important Note: if direction of pull is not in line with the eye bolt, and the eye bolt is extended, unwanted bending of the eye bolt can occur. In this situation fix the eye bolt hard up against the 30mm Shaft. Use a turnbuckle.

6

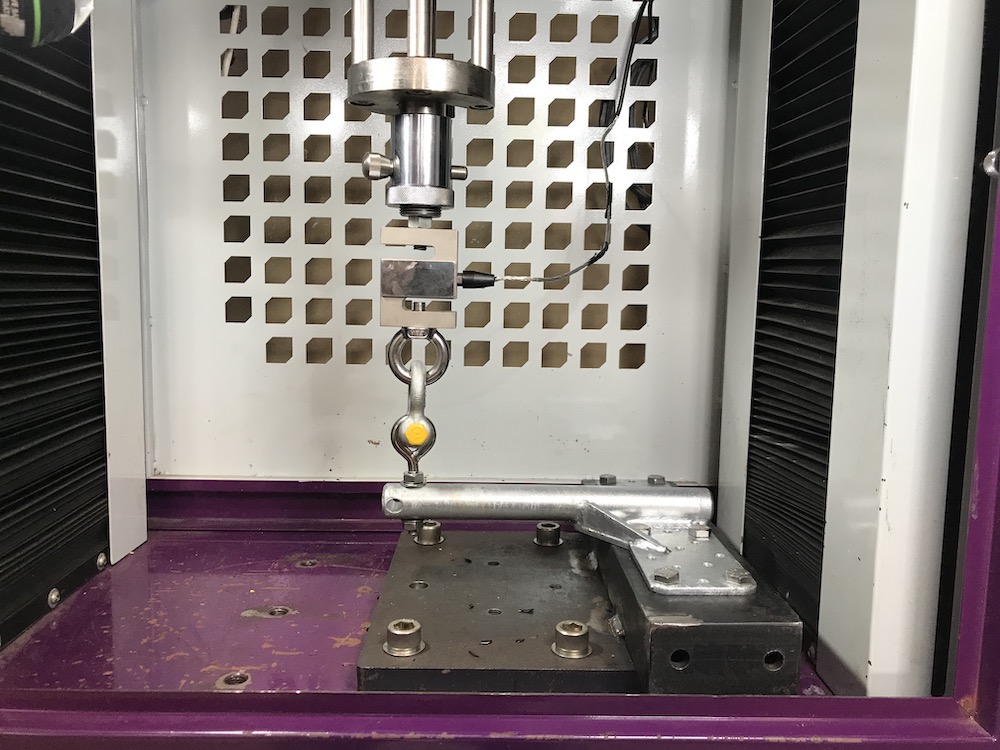

Picture 2 - Taken with 1250kgf load applied. Rafter Bracket returns to original shape when load is removed. No permanent deformation whatsoever.